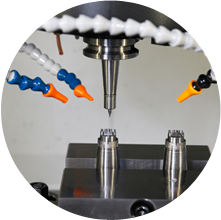

Moldmaking Division Monozukuri starts with superior mold construction.

Moldmaking with high precision and superior durability is essential to ensuring a stable, high-volume supply of high-quality, high-precision molded products. Newpla designs and makes all its own molds using 3D CAD/CAM. Our production accuracy is enhanced by constant maintenance. By combining the latest mold technology with ultra-precision machining technology that seeks precision at micron level, Newpla actively meets the need for diversified and complex molds for products manufactured to special standards and other such products.